USA

USA

Latin America

Brazil & Portugal

888-800-2310 (Toll Free) 989-681-2158 (Local/International) 740 E Monroe Road, St. Louis, MI 48880

517-579-3061 Teléfono en México: 55-5351-3093 info@brinechlor.com

55-13-997855697

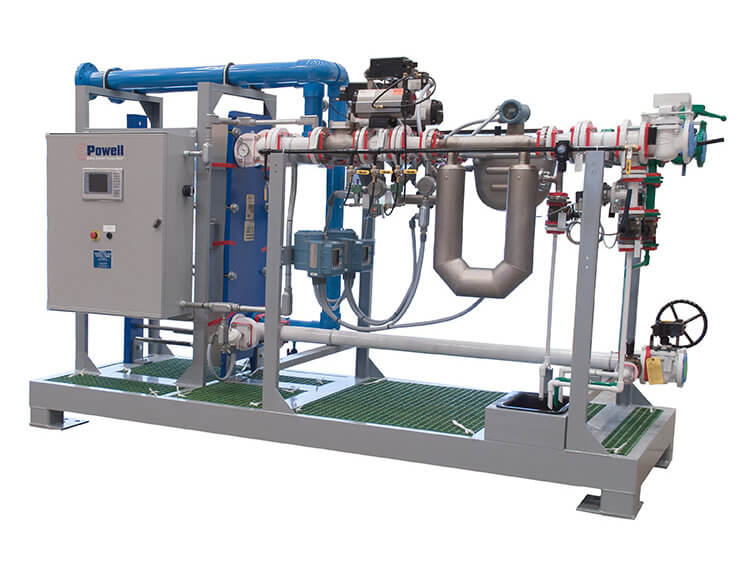

Powell Chemical Blending & Chemical Dilution Systems combine multiple raw material streams in precise ratios to accurately and repeatably produce mixtures, intermediates, and common or proprietary finished products. Outputs range from a few gallons (or liters) to tons per minute and automatically direct to drums, totes, storage tanks, filling operations, tank trucks, or railcars. Viscous, corrosive, abrasive, exothermic, and flammable raw materials can be safely controlled and properly combined.

Powell Chemical Blending & Dilution Systems are skid mounted, programmed, water tested, fully functional, and ready for quick and easy installation. Complete systems can include heat exchangers, supply pumps, motor starters, cooling water systems, network communications, and storage tank level control automation. They are constructed using a wide variety of materials and methods to meet required welding specifications and electrical codes. Customer recipes can easily be stored and accessed by touch screen control, and if process upsets occur, the system will instantly self-adjust material streams.